From Digital Design to Physical Object: A Comprehensive Analysis of the 3D Printing Workflow

Executive Summary

Additive manufacturing, commonly known as 3D printing, represents a paradigm shift in the creation of physical objects, transforming digital blueprints into tangible items with unprecedented speed and geometric freedom. This report provides an exhaustive analysis of the end-to-end 3D printing workflow, a multi-stage process that begins with conceptualization in a digital environment and culminates in a finished, functional component. The journey from intangible data to physical reality is navigated through four critical stages: Modeling, Slicing, Printing, and Post-Processing. Each stage presents a series of technological choices and trade-offs that directly influence the quality, cost, and performance of the final product.

The process commences with Modeling, where computer-aided design (CAD) software is used to create a precise three-dimensional digital model. This initial phase is governed by the principles of Design for Additive Manufacturing (DFAM), a holistic approach that requires designers to anticipate the physical constraints of the printing process, such as the need for support structures, minimum wall thickness, and material-specific behaviors. The digital model is then translated into a universally recognized file format—most commonly STL, OBJ, or the modern 3MF standard—each offering different capabilities for storing geometric, color, and manufacturing data.

The second stage, Slicing, acts as the crucial bridge between the digital model and the physical machine. Slicer software dissects the 3D model into hundreds or thousands of thin horizontal layers and generates a file of machine instructions known as G-code. This G-code dictates every movement of the printer, from the path of the print head to the temperature of the extruder and the rate of material deposition. The optimization of slicer settings is a critical lever for controlling the final object's properties, balancing the competing demands of speed, strength, and surface finish.

The Printing stage involves the physical fabrication of the object using one of several core technologies. This report focuses on the three most prevalent polymer-based methods: Fused Deposition Modeling (FDM), which extrudes molten thermoplastic; Stereolithography (SLA), which cures liquid resin with UV light; and Selective Laser Sintering (SLS), which fuses powdered polymer with a laser. The choice of technology is a pivotal decision, dictating material selection, resolution, mechanical properties, and the required post-processing steps. The expanding palette of materials—from basic plastics to engineering-grade composites and biocompatible resins—is the primary enabler of 3D printing's expansion from rapid prototyping to end-use part production.

Finally, raw prints undergo Post-Processing to become finished components. This "hidden factory" of additive manufacturing involves a range of technology-specific techniques, including support removal, chemical washing, UV curing, depowdering, sanding, and surface finishing. These steps are often labor-intensive and are critical for achieving the desired aesthetic quality and mechanical performance.

This comprehensive workflow is supported by a vibrant digital ecosystem of online model repositories, which are evolving from hobbyist sharing communities into professionalized marketplaces. The applications of this technology are transformative, enabling mass personalization and supply chain disruption across industries. In aerospace, it facilitates the creation of lightweight, optimized components. In healthcare, it delivers patient-specific implants and prosthetics. In consumer goods, it ushers in an era of on-demand, customized products. Ultimately, 3D printing's core value lies in its ability to decouple manufacturing cost from geometric complexity, paving the way for a new economic model based on mass personalization and distributed, on-demand production.

Chapter 1: The Additive Manufacturing Paradigm

1.1 Defining the Principles of Additive Manufacturing

Additive manufacturing, the formal term for 3D printing, is a production technique that creates a three-dimensional object from a computer-aided design (CAD) file by depositing material layer by layer.1 This method stands in stark contrast to traditional subtractive manufacturing processes, such as CNC milling or lathing, which begin with a solid block of material and remove portions of it to reveal the final shape.3 The fundamental principle of 3D printing is the sequential addition of material—be it plastic, metal, resin, or composite—to build an object from the ground up, one cross-section at a time.4

The process begins with a digital 3D model, which is then sliced into a series of thin horizontal layers. The 3D printer reads these layers as a set of instructions and deposits the chosen material according to the specified geometry for each layer. When one layer is complete, the build platform moves, and the next layer is deposited on top of it. This cycle repeats until the entire object is fabricated.4

This layer-by-layer approach unlocks the core value proposition of additive manufacturing: the ability to produce parts with immense geometric complexity, often at no additional cost compared to simpler designs. Traditional methods are constrained by tool access; for example, it is difficult to machine intricate internal channels or hollow structures. 3D printing, however, builds the object from the inside out, making such features not only possible but routine.7 This capability allows for the creation of lightweight lattice structures, consolidated assemblies that combine multiple parts into a single component, and organic shapes optimized for performance rather than manufacturability.7

1.2 The End-to-End Workflow: A Four-Stage Process Overview

The journey from a digital concept to a physical object is a structured, multi-stage process. While the specific tools and techniques may vary, the overarching workflow can be consistently divided into four primary stages: Modeling, Slicing, Printing, and Post-Processing.11 Understanding this sequence provides a clear framework for navigating the complexities of additive manufacturing.

Modeling: This is the genesis of the process, where a three-dimensional digital representation of the desired object is created. This is typically accomplished using specialized 3D modeling or CAD software. The designer can either create a model from scratch, modify an existing design, or use a 3D scanner to generate a model from a real-world object.5

Slicing: Once the digital model is complete, it must be translated into a language the 3D printer can understand. This is the role of "slicer" software. The slicer takes the 3D model file, divides it into hundreds or thousands of thin horizontal layers, and generates a file containing machine-specific instructions known as G-code. This file dictates the precise toolpaths, speeds, and temperatures the printer will use to build each layer.11

Printing: This is the stage where the digital becomes physical. The G-code file is sent to the 3D printer, which then begins the automated process of building the object layer by layer. The printer follows the G-code instructions meticulously, depositing, curing, or sintering material to form the final part.11

Post-Processing: A raw 3D print is rarely a finished product. The final stage involves a series of finishing steps to prepare the part for its intended use. This can include removing temporary support structures, cleaning away excess material, curing the part to achieve its final strength, sanding to improve surface finish, and painting or coloring for aesthetic purposes.11

It is critical to recognize that these four stages are not isolated but form a chain of dependencies. Decisions made early in the workflow have significant and often irreversible downstream consequences. For instance, the choice of printing technology in the third stage directly determines the necessary post-processing techniques in the fourth.13 A design choice made during the modeling stage, such as including a significant overhang, will necessitate the use of support structures, which must be accounted for in the slicing stage and physically removed during post-processing.6 Similarly, the selection of a specific material is constrained by the capabilities of the chosen printer technology and will influence the final mechanical properties of the object.4 This interconnectedness gives rise to the concept of "Design for Additive Manufacturing" (DFAM), an expert approach that involves thinking holistically about the entire process from the very beginning. An effective designer must not only create a digital model but must do so with a clear understanding of how it will be sliced, printed, and finished to achieve the desired outcome.

Chapter 2: Digital Genesis: Modeling and Design for 3D Printing

2.1 The Role of Computer-Aided Design (CAD) Software

The entire 3D printing workflow originates with a digital file, making computer-aided design (CAD) software the essential starting point for creation. CAD software provides the tools to translate an abstract idea into a precise, three-dimensional digital model that can be manipulated, analyzed, and ultimately sent to a printer for fabrication.18 It is the virtual workbench where objects are conceived and defined with dimensional accuracy, surface textures, and material properties before any physical material is consumed.11

The landscape of 3D design software is diverse, encompassing a range of tools tailored for different industries and applications. These can be broadly categorized:

3D CAD Software: Primarily used by engineers, architects, and product designers, these programs focus on creating precise, technical models with accurate dimensions and tolerances. They are the standard for designing mechanical parts, industrial equipment, and architectural structures.20

3D Modeling Software: Often used in media, entertainment, and graphic design, these tools excel at creating organic shapes, characters, and environments. They provide greater artistic freedom but may prioritize aesthetics over strict dimensional accuracy.20

Specialized Software: The field also includes highly specialized tools such as Building Information Modeling (BIM) software for construction, visual effects (VFX) software for film and games, and generative design platforms that use algorithms to create optimized forms.20

For the purpose of 3D printing, the software must not only facilitate the creation of a model but also ensure that the design is printable and optimized for the chosen manufacturing process. This involves features that can identify and repair errors in the model, simulate its performance under stress, and export it in a compatible file format.19

2.2 Comparative Analysis: Professional CAD Platforms

While countless modeling tools are available, a few professional-grade platforms have become industry standards for their robust feature sets tailored to additive manufacturing.

Autodesk Fusion is a comprehensive, cloud-based platform that integrates CAD, computer-aided manufacturing (CAM), and computer-aided engineering (CAE) into a single environment. This integration makes it particularly well-suited for modern, collaborative product development workflows.19 For 3D printing, Fusion offers a powerful suite of tools, including:

Parametric Modeling: Allows designs to be built around adjustable parameters, enabling easy and consistent updates to the model's geometry.19

Simulation: Provides built-in tools to test how a model will perform under real-world conditions, helping to identify structural weaknesses before printing.19

Mesh Editing: Enables the direct import, modification, and repair of mesh files (like STLs), which is crucial for preparing complex geometries for printing.19

Direct Export: Supports seamless export to industry-standard formats such as STL, OBJ, and 3MF, ensuring compatibility with slicers and printers.19

SOLIDWORKS is another dominant force in the professional CAD space, widely used for mechanical design and engineering. Its offerings, particularly under the "SOLIDWORKS for Makers" and "3DEXPERIENCE" platforms, include features specifically designed to optimize models for 3D printing.18 Key capabilities include:

Geometry Analysis: Tools that automatically identify potential problem areas for 3D printing, such as walls that are too thin or discontinuous faces.18

Topology Optimization: An advanced feature that algorithmically generates the most efficient shape for a part based on its functional constraints, removing material where it is not needed to create lightweight yet strong designs.18

Undercut Analysis: Helps designers identify areas that will require support structures, allowing them to modify the design to improve printability.18

While platforms like Fusion and SOLIDWORKS offer integrated solutions, other powerful tools like Autodesk Inventor are also used, especially for designing highly complex mechanical assemblies and machinery.12 The choice of platform often depends on the specific industry, the complexity of the project, and the need for collaborative features.

2.3 Fundamental Design Principles for Printability

A model that looks perfect on a computer screen may fail catastrophically during the printing process. This is because the digital environment is an idealized space without physical forces like gravity, internal stress, or thermal dynamics, all of which are present during fabrication.6 Adhering to a set of fundamental design principles is therefore essential to ensure a successful transition from digital to physical.

Wall Thickness: This is the most commonly overlooked yet critical aspect of design for 3D printing. In a digital environment, it is possible to create a surface with zero thickness, but in the physical world, every wall must have a substantial thickness to be structurally sound. Thin walls are prone to breaking, warping during the cooling process, or simply not printing at all. A general rule of thumb is to avoid designing any element with a thickness of less than 1 mm.6

Watertight Geometry: A 3D model intended for printing must be a "manifold" or "watertight" object. This means it must consist of a single, continuous outer surface with no holes or gaps. Any disconnected pieces within the geometry will be printed as separate, detached objects, and any holes in the mesh can confuse the slicer, leading to print failures.6

Support Structures and Overhangs: For layer-based technologies like FDM and SLA, each new layer must be deposited onto a layer below it. This creates a problem for features that overhang into empty space. Generally, any overhang with an angle greater than 45 degrees from the vertical will require a temporary support structure to be printed beneath it. These supports are later removed in post-processing. While necessary, they consume extra material and time and can leave marks on the surface. Good design practice involves orienting the model or modifying its geometry to minimize the need for supports.6 Powder-based technologies like SLS do not require dedicated support structures, as the surrounding unsintered powder provides natural support.6

Hollowing and Escape Holes: Printing large, solid objects can be time-consuming and expensive due to the amount of material required. For technologies like SLA and SLS, it is common practice to hollow out the interior of large models. This not only saves material and cost but also reduces production time and can prevent issues like warping caused by thermal stress.6 When a model is hollowed, it is crucial to include one or more "escape holes." These small openings allow uncured liquid resin (in SLA) or unsintered powder (in SLS) to be removed from the internal cavity during post-processing.6

Resolution and Tolerance: Every 3D printer has a maximum resolution, which defines the smallest feature size it can accurately reproduce. In general, details smaller than 0.1 mm will likely not be visible in the final print.6 Designers must also account for the printer's dimensional tolerance—the small deviation between the dimensions of the digital model and the final physical object. This tolerance must be considered when designing parts that need to fit together precisely.6

2.4 Advanced Modeling Techniques

Beyond the fundamental principles, advanced modeling techniques allow designers to fully leverage the unique capabilities of additive manufacturing to create highly optimized and innovative parts.

Parametric Modeling: This design approach is based on defining relationships and constraints between different geometric elements using parameters (e.g., variables for length, angle, or thickness). When a parameter is changed, the entire model automatically updates to maintain the defined relationships. This makes it incredibly efficient to iterate on designs and create families of related parts.19

Generative Design: This represents a paradigm shift in the design process. Instead of a human designer drawing a specific shape, they define the problem: key parameters such as loads, constraints, material properties, and manufacturing method. The software then uses AI-driven algorithms to explore thousands of potential design permutations, generating solutions that are optimized for performance metrics like strength-to-weight ratio.19

Simulation and Topology Optimization: Simulation tools allow designers to apply virtual forces, pressures, and thermal loads to a digital model to predict how it will behave in the real world. This helps identify and correct design flaws before committing to a physical print.19 Topology optimization is a form of simulation that automatically refines a part's geometry, adding material where stress is high and removing it from non-critical areas. This process results in organic, bone-like structures that are lightweight but exceptionally strong.18

Lattice Structures and Volumetric Modeling: 3D printing makes it possible to design parts with complex internal geometries. One powerful application of this is the creation of internal lattice structures. These repeating, interconnected struts can significantly reduce a part's weight and material consumption while maintaining a high degree of structural integrity. Volumetric modeling tools enable the design of these intricate, high-detail internal and external shapes.19

The rise of these advanced modeling paradigms marks a fundamental transition in engineering design, moving from forms dictated by human intuition and traditional manufacturing constraints to forms optimized by machine intelligence for performance. The organic, often non-intuitive shapes produced by generative design and topology optimization are frequently impossible to create using subtractive methods but are perfectly suited for the layer-by-layer fabrication of 3D printing. This creates a powerful symbiotic relationship: the demand for high-performance, lightweight components, particularly in industries like aerospace 7, drives the adoption of these advanced software tools. In turn, these tools produce complex geometries that can only be realized through additive manufacturing, reinforcing the value and necessity of the technology. This evolution represents a change in the role of the engineer—from being the sole creator of a design to becoming a curator of machine-generated solutions, defining problems and selecting the optimal outcome from a range of possibilities.

Chapter 3: The Digital Blueprint: A Comparative Analysis of 3D File Formats

Once a 3D model is finalized, it must be exported into a standardized file format that can be read by slicer software. This file acts as the digital blueprint, containing the geometric data that describes the object's shape. The choice of file format is a critical decision, as it determines what kind of information—from basic geometry to complex color and material data—is passed on to the next stage of the workflow. The historical development of these formats directly reflects the growing capabilities of 3D printing technology itself.

3.1 STL (STereoLithography): The Universal Standard

The STL file format, whose name originates from Stereolithography, has been the de facto standard for 3D printing since its release in 1987.21 Its longevity is a testament to its simplicity and universal compatibility; virtually every piece of 3D printing hardware and software in the world can read and process an STL file.22 An STL file describes the surface geometry of a 3D object using a collection of interconnected triangles, a method known as tessellation.21

However, the primary strength of the STL format—its simplicity—is also its greatest weakness. An STL file contains nothing more than the raw, unstructured geometric data of the triangulated surface. It is incapable of storing any additional information, such as:

Color

Texture

Material properties

Scale or units 21

This was not a significant limitation in the early days of 3D printing, when machines could only print with a single material in a single color. However, with the advent of modern multi-material and multi-color printers, the inability of the STL format to carry this richer data has become a major bottleneck.22 Furthermore, the format is prone to errors such as holes, gaps, and overlapping triangles, which can result from a poor conversion process and often require manual repair before a model can be successfully sliced.22

3.2 OBJ: Incorporating Color and Texture Data

The OBJ file format emerged from the 3D graphics and animation industry, where the need to represent color and texture has long been paramount.23 Unlike STL, the OBJ format was designed to store more than just basic geometry. It can contain data describing the object's shape as well as its surface color and texture map information.22

This additional data is often stored in a companion file with a .mtl (Material Template Library) extension, which is referenced by the main .obj file.22 This capability makes OBJ a superior choice for applications where visual appearance is critical, such as printing full-color figurines, detailed architectural models, or objects derived from 3D scans that have captured surface texture.24 While more capable than STL, OBJ is not as universally supported by all slicers and printers, and compatibility must be verified, especially when dealing with complex texture data.24 For many applications, converting an OBJ to an STL is still a common step to ensure broad compatibility, though this process strips away the valuable color and texture information.24

3.3 3MF (3D Manufacturing Format): The Modern Standard

The limitations of both STL and OBJ in the face of increasingly sophisticated printing hardware led to the development of the 3D Manufacturing Format (3MF). Spearheaded by the 3MF Consortium—a group of industry leaders including Microsoft, Autodesk, HP, and Stratasys—3MF was designed from the ground up to be a modern, comprehensive, and unambiguous file format for additive manufacturing.21

Based on XML, 3MF is not a single file but rather a compressed package (similar to a .zip archive) that acts as a container for a complete set of manufacturing data.21 A single .3mf file can contain:

Advanced Geometry: It describes geometry accurately, using methods like curved triangular tessellations, and has a clear definition of manifoldness, which helps prevent the errors common in STL files.21

Full Color, Material, and Texture Information: It can store detailed data for multi-property parts, making it ideal for the most advanced multi-material and full-color printers.22

Print and Slicer Settings: It can embed printer profiles and specific slicer settings, such as infill patterns, support structures, and layer heights, directly within the file. This ensures that a model will be printed exactly as the designer intended, regardless of the machine used.21

Metadata: It can include other useful information like the designer's name, a description of the part, and even a thumbnail image for easy identification.21

A key advantage of 3MF is its efficiency. For example, if a print job contains multiple copies of the same object, an STL file would have to duplicate the entire mesh geometry for each copy. A 3MF file, by contrast, can store the mesh once and simply reference it multiple times at different locations, significantly reducing file size.21 As a result of these features, 3MF files are considered "ready-to-print," bundling all the necessary information into a single, portable, and error-free package.22

The evolution of these file formats clearly mirrors the progression of 3D printing technology. STL was sufficient for the initial era of simple, single-material machines. The rise of multi-color printing capabilities brought OBJ into the ecosystem. Finally, the emergence of complex, multi-material manufacturing systems with intricate process controls created a data bottleneck that older formats could not handle, necessitating the creation of a comprehensive standard like 3MF. The file format is therefore not merely a technical specification; it is a direct enabler of technological innovation. The rich, all-in-one data structure of 3MF is paving the way for more intelligent, automated, and repeatable manufacturing workflows, where the designer's full intent—from geometry to material to print settings—is seamlessly and unambiguously transferred to the machine.

Table 3.1: Comparative Analysis of 3D Printing File Formats

To provide a clear, at-a-glance summary of these key formats, the following table compares their characteristics and primary applications.

Feature

STL (STereoLithography)

OBJ (Object File)

3MF (3D Manufacturing Format)

Extension

.stl

.obj (with optional .mtl)

.3mf

Data Supported

Geometry only

Geometry, Color, Texture

Geometry, Color, Texture, Materials, Slicer Settings, Metadata

File Structure

Raw, unstructured triangular mesh

Vertex-based geometry with references to a separate material file

XML-based compressed archive (like a.zip file) containing all data

Key Advantage

Universal compatibility; supported by virtually all hardware and software

Supports color and texture data, making it suitable for visual models

All-in-one data package; error-free, efficient, and unambiguous

Key Limitation

No support for color, material, or other metadata; prone to geometric errors

Texture/color data is in a separate file; not as universally supported as STL

Newer format, so adoption is not yet as widespread as STL

Primary Use Case

Prototyping, simple mechanical parts, and ensuring maximum compatibility

Full-color figurines, architectural models, 3D scanned objects

Professional multi-material/multi-color prints, sharing complete print jobs

Chapter 4: From Model to Machine: The Critical Role of Slicing and G-Code

4.1 The Function of Slicer Software

After a 3D model has been designed and exported to a suitable file format, it must be prepared for the physical printing process. This crucial translation is performed by a specialized piece of software known as a "slicer".12 The slicer's primary function is to convert the continuous geometry of a 3D model into a series of discrete instructions that a 3D printer can execute. It achieves this by digitally "slicing" the model into hundreds or thousands of thin, horizontal layers, and for each layer, it generates the precise toolpaths the printer's head will follow.6

Beyond simply dividing the model into layers, the slicer is responsible for calculating and generating several critical elements required for a successful print:

Infill: Solid objects are rarely printed completely solid. To save material and time, the slicer generates an internal support structure known as infill, which can take the form of various patterns like grids, honeycombs, or triangles.25

Support Structures: For any parts of the model that overhang, the slicer automatically generates temporary support structures to prevent the material from drooping or collapsing during the print.25

Adhesion Aids: The slicer can add features like brims or rafts around the base of the model to improve its adhesion to the build plate and prevent warping.25

The output of the slicer is a G-code file, which contains the comprehensive set of commands for the printer.12 The market for slicer software is robust, with several popular options available, many of which are open-source. Prominent examples include Ultimaker Cura, PrusaSlicer (a fork of Slic3r), and ideaMaker, each offering a user-friendly interface alongside advanced configuration options.12

4.2 Decoding G-Code: The Language of 3D Printers

G-code is the standard programming language used to provide instructions to computer numerical control (CNC) machines, a category that includes 3D printers.25 It is a plain-text language, and the .gcode file generated by the slicer is essentially a long list of sequential commands that tell the printer exactly what to do at every moment of the print job.11 While most users never need to write G-code manually, a basic understanding of its structure is invaluable for troubleshooting prints and comprehending the inner workings of the machine.27

G-code commands are typically organized into two main categories:

G-commands (General Commands): These primarily control the motion of the printer's axes (X, Y, and Z) and the extruder (E). The most common command in any G-code file is G1, which instructs the printer to perform a linear movement to a specified coordinate while extruding a certain amount of material.25 Other essential G-commands include G28 (home all axes to their origin points) and G90/G91 (set positioning to absolute or relative coordinates).25

M-commands (Miscellaneous Commands): These control all other functions of the machine that are not related to movement. This includes managing temperatures, fan speeds, and other system-level operations.25 Key M-commands include M104 (set the extruder temperature and continue) and M109 (set the extruder temperature and wait for it to be reached), M140/M190 for the heated bed, and M106/M107 to turn the part cooling fan on and off.25

A typical G-code file begins with a startup sequence that prepares the machine for printing. An annotated example of such a sequence might look like this 28:

G-Code

G90 ; Set to absolute positioning mode

M82 ; Set extruder to absolute mode

M104 S200 ; Set extruder temperature to 200°C (don't wait)

M140 S60 ; Set bed temperature to 60°C (don't wait)

G28 ; Home all axes (X, Y, Z)

G29 ; Perform auto bed leveling routine

M109 S200 ; Wait for extruder to reach 200°C

M190 S60 ; Wait for bed to reach 60°C

G1 Z0.2 F1200 ; Move to the starting height for the first layer

Following this preamble, the file will contain thousands of G1 commands, each defining a small segment of the toolpath for every layer of the object.

4.3 Optimizing Slicer Settings for Quality, Speed, and Strength

While the slicer automates the complex task of generating G-code, it provides the user with a vast array of settings to control and optimize the final output. The slicer acts as the critical nexus where the idealized digital model meets the physical realities of the printing process. It is at this stage that abstract goals—such as the need for a quick prototype versus a strong functional part—are translated into quantifiable machine instructions.

A single digital model can be transformed into a wide spectrum of physical objects with vastly different properties simply by altering the slicer settings. Key parameters and their associated trade-offs include:

Layer Height: This determines the vertical resolution of the print. A lower layer height (e.g., 0.1 mm) produces a smoother, more detailed surface finish but significantly increases the print time. A higher layer height (e.g., 0.3 mm) prints much faster but results in more visible layer lines.16

Infill Density and Pattern: Infill is the internal structure of the print. A higher infill density (e.g., 80%) creates a stronger, heavier, and more durable part but consumes more material and time. A lower density (e.g., 15%) is suitable for visual models where strength is not a priority. The pattern of the infill (e.g., grid, gyroid, honeycomb) can also affect the part's mechanical properties in different directions.

Print Speed: This setting controls how fast the print head moves. Higher speeds reduce print time but can lead to lower quality, such as ringing or poor layer adhesion. Finding the optimal speed is a balance between efficiency and quality.

Temperature: The temperatures of the extruder nozzle and the heated bed are critical for proper material extrusion and adhesion. These settings are material-specific and must be dialed in correctly to prevent issues like under-extrusion or warping.

Support Settings: The user can control where and how support structures are generated, including their density and the type of interface with the model, which affects how easily they can be removed.

Mastery of 3D printing, therefore, is not just about creating a good digital model; it is about developing a deep understanding of how these slicer settings interact to influence the final physical object. The slicer is the most powerful tool for optimization in the entire workflow, allowing an operator to precisely balance the competing demands of quality, speed, and strength to meet the specific requirements of any given project.

Chapter 5: A Taxonomy of 3D Printing Technologies

The term "3D printing" encompasses a variety of distinct processes, each with its own method for building objects layer by layer. While numerous technologies exist, the polymer-based additive manufacturing landscape is dominated by three primary methods: Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS). The choice of technology is one of the most consequential decisions in the workflow, as it dictates everything from material compatibility and part resolution to mechanical performance and post-processing requirements.16

5.1 Fused Deposition Modeling (FDM) / Fused Filament Fabrication (FFF)

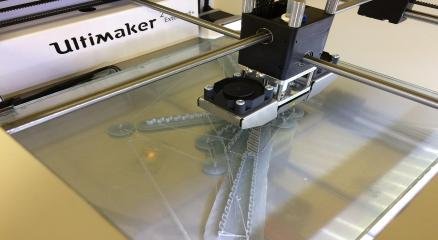

Fused Deposition Modeling, also known by the open-source term Fused Filament Fabrication, is the most widely recognized and accessible form of 3D printing.11 The process is conceptually simple, often compared to operating a sophisticated, computer-controlled hot glue gun.4

Process: A solid thermoplastic filament is unwound from a spool and fed into a heated extruder, or "print head." The extruder melts the filament and deposits the molten plastic through a small nozzle onto a build platform. The print head moves along the X and Y axes to draw the shape of a single layer. Once the layer is complete, the build platform lowers slightly along the Z axis, and the process repeats, building the object from the bottom up.4 For features with overhangs, the printer deposits temporary support structures that are removed after the print is complete.29

Characteristics: FDM is celebrated for its affordability, ease of use, and broad range of available materials, making it a popular choice for hobbyists, educators, and businesses creating functional prototypes and rapid tooling.4 However, its primary drawbacks are related to resolution and mechanical properties. The nature of the extrusion process results in visible layer lines, especially on curved surfaces, leading to a rougher surface finish compared to other technologies.16 Furthermore, FDM parts exhibit anisotropy, meaning they are mechanically weaker in the vertical (Z) direction because the layers are fused together rather than being chemically bonded. This can cause parts to delaminate or break along the layer lines when under stress.4

5.2 Stereolithography (SLA)

Stereolithography holds the distinction of being the first commercialized 3D printing technology and remains the gold standard for achieving high detail and smooth surface finishes.5

Process: SLA operates on the principle of photopolymerization. A build platform is submerged in a vat of liquid photopolymer resin. A highly precise ultraviolet (UV) laser or a digital light projector (in a variation called DLP) selectively traces the cross-section of a layer onto the surface of the resin, causing it to cure and solidify. After a layer is formed, the platform moves up (or down, in inverted systems) by a small increment, and a fresh layer of resin is exposed for the next curing cycle. This process continues until the part is complete.2 Similar to FDM, SLA requires support structures for overhanging features.29

Characteristics: The key strength of SLA is its exceptional precision. It can produce parts with incredibly fine details (features as small as 0.1 mm) and a surface finish that is nearly indistinguishable from that of an injection-molded part.4 This makes it the ideal technology for applications where aesthetic quality and intricate detail are paramount, such as jewelry casting masters, dental models, and visual prototypes.4 The trade-offs include higher equipment and material costs compared to FDM, and a more involved and messy post-processing workflow that requires washing the part in a solvent and then curing it in a UV chamber to achieve its final mechanical properties.16 Additionally, standard resin parts can be brittle and may degrade with prolonged exposure to UV light.4

5.3 Selective Laser Sintering (SLS)

Selective Laser Sintering is an industrial-grade technology renowned for its ability to produce strong, functional parts with a high degree of design freedom.16

Process: The SLS process begins with a thin layer of polymer powder (most commonly nylon) being spread across a build platform. A high-powered CO2 laser then scans the cross-section of the layer, selectively heating and fusing (sintering) the powder particles together to form a solid. After the layer is complete, the platform lowers, a fresh layer of powder is applied, and the process repeats.6

Characteristics: The most significant advantage of SLS is that it is a self-supporting process. The unsintered powder that surrounds the part during the build acts as a natural support structure, eliminating the need for dedicated, manually removed supports.6 This grants designers almost unlimited geometric freedom, allowing for the creation of complex, interlocking, and movable parts that would be impossible to produce with FDM or SLA. SLS parts possess excellent, nearly isotropic mechanical properties, making them strong and durable enough for end-use applications and functional testing.16 The main disadvantages are the high initial cost of the equipment, the need for a controlled facility environment, and a mandatory cooling period after printing that can last up to 12 hours.16 The resulting parts have a slightly rough, grainy surface finish with a matte appearance.16

Table 5.1: FDM vs. SLA vs. SLS Technology Matrix

The following matrix provides a detailed comparison of these three core technologies across a range of critical metrics, designed to aid in selecting the most appropriate process for a given application.

Metric

Fused Deposition Modeling (FDM)

Stereolithography (SLA)

Selective Laser Sintering (SLS)

Process

Extrusion of molten thermoplastic filament

Curing of liquid photopolymer resin with UV light

Fusing of polymer powder with a high-powered laser

Materials

Thermoplastics (PLA, ABS, PETG, TPU, Nylon)

Photopolymer Resins (Standard, Tough, Flexible, Castable)

Polymer Powders (Nylon PA11/PA12, TPU)

Min. Feature Size

~ mm

~ mm

~ mm

Layer Height

mm

mm

mm

Dimensional Accuracy

mm

mm

mm

Surface Finish

Rough, visible layer lines

Very smooth, comparable to injection molding

Slightly rough, grainy matte finish

Strengths

Low cost, easy to use, wide material variety

High resolution, excellent surface finish, high accuracy

High design freedom (no supports), strong functional parts, good for batch production

Weaknesses

Low resolution, anisotropic strength, visible layer lines

Higher cost, messy post-processing, parts can be brittle

Very high equipment cost, long cooling times, grainy surface

Equipment Cost

Low (starts ~)

Medium (starts ~ for professional)

High (starts ~ for benchtop industrial)

Material Cost

Low (~)

Medium (~)

High (~)

Typical Applications

Hobbyist projects, functional prototypes, jigs and fixtures

Visual prototypes, dental models, jewelry patterns, microfluidics

End-use parts, complex geometries, functional prototypes, low-volume production

Post-Processing

Support removal, sanding

Washing in solvent, UV post-curing, support removal

Depowdering, media blasting/tumbling, dyeing

Chapter 6: The Palette of Creation: Materials in Additive Manufacturing

The capabilities of any 3D printing technology are fundamentally defined by the materials it can process. The evolution of additive manufacturing from a tool for creating simple visual models to a viable method for producing functional, end-use parts is primarily a story of advances in materials science. The development of polymers with specific engineering properties—such as high strength, heat resistance, flexibility, and biocompatibility—has unlocked applications in the most demanding industries.7 Each of the core printing technologies relies on a distinct category of materials tailored to its specific fabrication process.

6.1 Thermoplastic Filaments for FDM

FDM printers work with thermoplastics, which are polymers that become molten when heated and solid when cooled. These materials are supplied as long, continuous filaments wound onto spools.4 The range of available filaments is vast, offering a wide spectrum of properties.

Standard Plastics:

PLA (Polylactic Acid): Derived from renewable resources like corn starch, PLA is biodegradable and one of the easiest materials to print with, exhibiting minimal warping. It is a favorite among hobbyists and is ideal for creating prototypes and decorative items that do not require high strength or heat resistance.17

ABS (Acrylonitrile Butadiene Styrene): Known for its strength, durability, and higher temperature resistance, ABS is a popular choice for creating functional parts that need to withstand stress, such as automotive components or electronic enclosures. It is more challenging to print than PLA, often requiring a heated build chamber to prevent warping.17

PETG (Polyethylene Terephthalate Glycol): This material offers a compelling balance of properties, combining much of the ease of printing of PLA with the strength and durability of ABS. It is also known for its chemical resistance and clarity.17

Flexible Filaments:

TPU (Thermoplastic Polyurethane) and TPE (Thermoplastic Elastomer): These are rubber-like materials that provide excellent flexibility and elasticity. They are used to create objects that need to bend or stretch, such as phone cases, gaskets, and wearable items.17

Engineering Filaments:

Nylon (Polyamide): Valued for its exceptional strength, flexibility, and durability, nylon is ideal for printing robust functional parts like gears, living hinges, and other components that require high resilience and wear resistance.17

PC (Polycarbonate): One of the strongest consumer-grade filaments, PC offers outstanding impact resistance and high heat tolerance, making it suitable for creating protective gear and demanding functional prototypes.17

Composite Filaments:

These materials consist of a base thermoplastic (like PLA, ABS, or Nylon) that has been reinforced with short strands of other materials to enhance its properties. Carbon fiber-filled filaments, for example, offer significantly increased stiffness and strength, while glass fiber-filled filaments provide improved durability.17

6.2 Photopolymer Resins for SLA

SLA technology relies on photopolymers, which are liquid resins that solidify when exposed to UV light. These resins are formulated to provide a wide range of optical, mechanical, and thermal properties, often mimicking those of traditional thermoplastics.17

Standard Resins: These are general-purpose resins that offer a good balance of cost, speed, and properties. They are excellent for creating high-detail visual prototypes with a smooth surface finish.17

Tough and Durable Resins: These engineering resins are formulated to simulate the strength and impact resistance of ABS plastic. They are ideal for creating functional prototypes and assemblies that need to withstand mechanical stress.17

Flexible and Elastic Resins: These resins mimic the properties of rubber and silicone, allowing for the creation of parts that can be bent, stretched, and compressed. They are used for applications like gaskets, seals, and ergonomic soft-touch components.17

Specialty Resins: The versatility of resin chemistry has led to the development of highly specialized materials for specific industries. These include castable resins that burn out cleanly, used for creating masters for jewelry and metal casting; biocompatible resins certified for medical and dental applications like surgical guides and hearing aids 29; and high-temperature resins that can withstand heat for applications like injection mold tooling.

6.3 Polymer Powders for SLS

SLS printers primarily use powdered thermoplastics, which are fused together by a laser. The material selection is more limited than for FDM but is focused on producing high-performance, engineering-grade parts.17

Nylon (PA11, PA12): Nylon is the workhorse material for SLS 3D printing. It is a highly capable engineering thermoplastic that offers an excellent combination of strength, durability, and flexibility. Parts printed in nylon are lightweight and stable against impact, chemicals, and heat, making them suitable for a wide range of functional end-use applications. Biocompatible grades of nylon are also available for medical use.17

TPU: Flexible, rubber-like TPU powder is also available for SLS, enabling the production of highly elastic and durable parts without the need for support structures, which is a significant advantage over FDM for creating complex flexible components.16

6.4 Other Material Categories

While this report focuses on polymer-based printing, the field of additive manufacturing extends to a much broader range of materials, highlighting its versatility and growing industrial impact.

Metals: Technologies like Direct Metal Laser Sintering (DMLS) and Selective Laser Melting (SLM) can print with metal powders, including stainless steel, titanium, aluminum, and various alloys. These processes are used to create high-strength, complex parts for the aerospace, automotive, and medical industries.17

Ceramics: Specialized 3D printing processes can create parts from technical ceramics like aluminum oxide and silicon carbide, which offer high heat and wear resistance.32

Glass and Sand: Other technologies can bind materials like sand to create large-scale molds for metal casting or even print optically clear glass components.

The continuous development of new materials is the primary force driving the expansion of 3D printing's applications. As materials scientists create polymers and composites that can meet the stringent performance requirements of industries like aerospace and healthcare, the technology transitions from a prototyping tool into a legitimate and often superior method for manufacturing final products. The future of additive manufacturing is thus inextricably linked to the future of materials science.

Chapter 7: The Final Polish: A Guide to Post-Processing Techniques

7.1 The Necessity of Post-Processing

The automated act of 3D printing is only one part of the manufacturing process. A raw part taken directly from the printer is rarely ready for its final application. Post-processing encompasses all subsequent steps required to clean, finish, and enhance the printed object, transforming it from a rough output into a functional or aesthetically pleasing component.11 These techniques are not merely optional; they are a critical stage of the workflow for improving surface quality, dimensional accuracy, and mechanical properties.13 The specific post-processing steps required are heavily dependent on the printing technology used, the material, and the intended use of the part.

The effort and cost associated with post-processing can be substantial, representing a "hidden factory" within the additive manufacturing workflow. While the printing itself is automated, many finishing steps are manual and labor-intensive, such as sanding or support removal.29 This has a direct impact on the scalability and true cost of production. For example, a complex FDM part with many supports may have a low print cost but a very high labor cost for finishing, making it uneconomical at scale. Conversely, an SLS part has a higher print cost but requires minimal manual labor for post-processing, making it more cost-effective for batch production.14 Therefore, a comprehensive understanding of post-processing is essential for accurately assessing the viability of a 3D printing application.

7.2 Technology-Specific Cleaning and Curing

The first step after a print is complete is to clean the part and remove it from the build environment. This initial process varies significantly between the major printing technologies.

FDM: The primary cleaning step for FDM prints is support removal. For prints that use insoluble supports (made from the same material as the part), this is a manual process that involves carefully breaking away the support structures using tools like pliers, flush cutters, or hobby knives.13 For printers equipped with dual extruders, it is possible to use a soluble support material like PVA (for PLA) or HIPS (for ABS). In this case, the entire print is submerged in a liquid bath (water for PVA, limonene for HIPS), which dissolves the supports away, leaving the main part untouched. This method is less likely to damage the part and is ideal for complex internal geometries.13

SLA: SLA parts emerge from the printer coated in a layer of sticky, uncured liquid resin. This requires a multi-step cleaning and curing process. First, the part must be washed by submerging and agitating it in a solvent, typically isopropyl alcohol (IPA), to dissolve and remove all residual resin.13 After washing and drying, the part is still in a "green" state and has not yet reached its final mechanical properties. It must then be post-cured by exposing it to a combination of UV light and heat in a specialized curing chamber. This final step fully polymerizes the resin, maximizing the part's strength and stability.13

SLS: SLS parts are encased in a block of unsintered powder when the print finishes. The first step is depowdering, which involves excavating the parts from the powder cake and removing all the loose powder from their surfaces. This is typically done manually with brushes and compressed air in a dedicated cleaning station. Automated systems that use vibration or tumbling are also available to streamline this process for batch production.13

7.3 Surface Finishing Techniques

After the initial cleaning, various techniques can be employed to improve the surface finish of the part, primarily by reducing or eliminating the visible layer lines inherent in the printing process.

Sanding: This is the most fundamental and widely used surface finishing technique. It involves manually or mechanically abrading the surface of the part with sandpaper of progressively finer grits. The process typically starts with a coarse grit (e.g., 80-120) to remove major blemishes like support marks, and then moves to finer grits (e.g., 600, 1000, 1500) to smooth the surface. Wet sanding, where the part and sandpaper are kept wet, is often used in the final stages to achieve a glass-like, polished finish.11

Media Blasting and Tumbling: These methods are common for SLS parts. Media blasting involves propelling a stream of abrasive material, such as glass or plastic beads, at the part's surface to remove any remaining powder and create a uniform, smooth matte finish.14 Media tumbling places parts in a vibrating or rotating barrel with abrasive media, which smooths all surfaces simultaneously and is highly effective for processing many parts at once.15

Chemical Vapor Smoothing: This is a more advanced technique used to achieve a glossy, injection-molded appearance, particularly on parts made from ABS or ASA. The part is exposed to a chemical solvent vapor (most commonly acetone for ABS) in a controlled chamber. The vapor condenses on the surface and slightly melts the outer layer of plastic, which flows together to eliminate layer lines. While highly effective, this process must be carefully controlled to avoid melting away fine details.13

7.4 Enhancement and Assembly Processes

Post-processing can also be used to enhance the mechanical properties of a part or to assemble larger objects.

Annealing: This is a thermal treatment that involves heating a 3D printed part to a temperature below its melting point and then cooling it in a controlled manner. This process helps to relieve the internal stresses that build up during printing and can significantly improve the adhesion between layers, resulting in a stronger and more durable part.15

Painting and Dyeing: For a professional aesthetic finish, parts can be painted. This usually involves sanding the surface smooth, applying a layer of primer to fill in small imperfections and create a uniform base, and then applying coats of paint with a brush or spray can.11 Due to their porous nature, SLS parts made from nylon are particularly well-suited to dyeing. The parts are submerged in a heated dye solution, which permeates the material to provide a vibrant, durable color throughout the part.15

Gluing and Welding: 3D printing is often used to create objects that are larger than the printer's build volume. This is achieved by splitting the model into smaller pieces, printing them separately, and then joining them together. Strong adhesives like cyanoacrylate (super glue) or two-part epoxies are commonly used for gluing. For certain plastics like ABS, a solvent like acetone can be used for welding, as it chemically melts the surfaces together to create a very strong bond.13

Chapter 8: The Global Workshop: Navigating Online Model Repositories

8.1 The Role of Digital Marketplaces

The proliferation of 3D printing has been fueled not only by advancements in hardware but also by the growth of a vast digital ecosystem. At the heart of this ecosystem are online model repositories—websites that serve as global libraries and marketplaces for 3D printable files. These platforms are crucial hubs for the 3D printing community, providing a space where designers, engineers, hobbyists, and professionals can share, download, buy, and sell digital designs.12 For many users, these repositories are the primary source of content, offering millions of pre-made models that eliminate the need to design every object from scratch.

8.2 Analysis of Leading Platforms

The landscape of model repositories is dynamic and competitive, with several major platforms catering to different segments of the user base.

Thingiverse: Launched in 2008 by MakerBot Industries, Thingiverse is the oldest and largest repository of 3D models, hosting over two million free-to-download files.35 Its massive library and long history have made it a cornerstone of the maker community. For many years, it has held the top position in user search interest, demonstrating its immense influence and brand recognition.37 However, the platform has been criticized for its aging interface and lack of updates, which has created an opening for newer competitors.37

Printables: Created by Prusa Research, a leading 3D printer manufacturer, Printables has rapidly grown to become a major challenger to Thingiverse's dominance.35 The platform is known for its modern, reliable, and ad-free user experience. It actively fosters community engagement through frequent design contests and a rewarding system for creators.38 While it started as a completely free repository, it has recently introduced the 'Printables Store,' allowing designers to sell their models, signaling a shift towards a hybrid free-and-paid model.38

Cults3D: As a leading independent marketplace, Cults3D has established itself as a premier destination for high-quality designs. It offers a curated selection of both free and paid models, with a strong emphasis on aesthetic and artistic creations.38 The platform is popular among professional designers as it provides a robust system for monetizing their work, claiming to give 80% of revenue back to the creators.38 It supports a wide range of file formats, including STL, OBJ, 3MF, and various CAD files.38

MyMiniFactory: This platform operates as a curated marketplace with a strong focus on quality control. MyMiniFactory guarantees that all models available on its site are 100% printable, having been vetted by both software checks and community testing.38 While it offers many free files, its primary focus is on premium, paid content. It has carved out a significant niche in the tabletop gaming community, offering a vast collection of high-detail miniatures and figurines.35

8.3 Marketplace Dynamics and Ecosystem

The ecosystem of model repositories is maturing, with increasingly sophisticated dynamics and business models.

Free vs. Paid Models: The initial ethos of the maker movement, embodied by Thingiverse, was centered on free and open sharing of designs. While this remains a vital part of the community, there has been a significant shift towards a professionalized "creator economy." Platforms like Cults3D, MyMiniFactory, and now Printables have introduced robust monetization tools, allowing talented designers to earn a living from their creations.35 This incentivizes the production of higher-quality, more complex, and better-documented models, benefiting the entire ecosystem.

Specialized and Professional Repositories: Beyond the general-purpose platforms, several repositories cater to specific professional needs. GrabCAD, for example, is a community for engineers and product designers, hosting a massive library of CAD files, although not all are optimized for 3D printing.35 CGTrader is a large marketplace for professional 3D artists, offering models for gaming, animation, and AR/VR, in addition to a substantial collection of 3D printable files.35

Meta-Search Engines: With millions of models scattered across dozens of websites, finding a specific design can be challenging. This has given rise to meta-search engines like Yeggi, which do not host files themselves but instead index multiple repositories. They function like a Google for 3D models, allowing users to search the entire ecosystem from a single interface and providing links to the original source pages.38 Yeggi is the clear leader among these search services, indexing nearly 5 million models.37

This evolution from a hobbyist-driven sharing culture to a professionalized creator economy marks a significant maturation of the 3D printing market. The initial phase, dominated by Thingiverse, was about establishing a critical mass of content and proving the concept of a shared digital library. The current phase is characterized by a "flight to quality," where users and businesses are increasingly willing to pay for reliable, well-designed, and guaranteed-printable digital assets. This professionalization is not only creating viable career paths for digital designers but is also essential for expanding the use of 3D printing into more critical commercial and industrial applications where quality and dependability are non-negotiable.

Chapter 9: Industry Transformation: Applications of 3D Printing

The true impact of 3D printing is measured by its ability to solve real-world problems and create value in various industries. By fundamentally altering the relationship between design, manufacturing, and cost, additive manufacturing is not just an alternative production method but a catalyst for innovation. Its core value proposition—the decoupling of geometric complexity from manufacturing cost—enables a paradigm shift from the mass production of standardized goods to the mass personalization of tailored solutions. This capability is driving transformative changes in sectors as diverse as aerospace, healthcare, and consumer goods.

9.1 Case Study: Aerospace and Defense

The aerospace industry was one of the earliest adopters of 3D printing and continues to be at the forefront of its application, driven by an relentless pursuit of performance, safety, and efficiency.8 The technology's impact is felt across the entire product lifecycle.

Rapid Prototyping: In an industry where development cycles are long and costly, 3D printing dramatically accelerates the process. Aerospace engineers can now design a component, print a physical prototype in-house, and test its form, fit, and function in a matter of days, rather than the weeks or months required for traditional prototyping methods. This allows for more design iterations in a shorter period, leading to better-optimized and more reliable final parts.8

Tooling, Jigs, and Fixtures: The assembly of an aircraft requires thousands of custom tools, jigs, and fixtures to hold components in place during manufacturing. Traditionally, these tools were machined from metal, an expensive and time-consuming process. By 3D printing these manufacturing aids on-demand using durable polymers, aerospace companies can achieve substantial time and cost savings, reported to be between 60% and 90%.7

End-Use Parts and Lightweighting: Weight is a critical factor in aircraft design, as it directly impacts fuel efficiency and payload capacity.7 3D printing enables two key strategies for weight reduction. First, lightweighting through topology optimization and generative design creates parts with complex, organic geometries and internal lattice structures that are significantly lighter than their solid counterparts but just as strong.7 Second, part consolidation allows engineers to redesign an assembly of multiple components into a single, complex 3D printed part. This not only reduces weight but also eliminates potential points of failure at joints and fasteners, simplifying assembly and improving reliability.7 As a result, modern commercial aircraft can have over 1,000 3D-printed parts, from non-critical interior components like air ducts and panels to flight-critical metal parts like fuel nozzles and turbine blades.7

9.2 Case Study: Healthcare and Medicine

3D printing is revolutionizing healthcare by enabling an unprecedented level of personalization in patient care. By using medical imaging data from CT or MRI scans as a direct input for the manufacturing process, clinicians can create devices and tools that are perfectly tailored to an individual patient's unique anatomy.3

Patient-Specific Implants: For procedures like cranial or orthopedic reconstruction, surgeons can now use 3D printing to create custom implants that perfectly match the patient's bone structure. This eliminates the need to manually shape and alter standard-sized implants during surgery, which significantly reduces operating time, minimizes complications, and leads to better patient outcomes and faster recovery.3 These implants are often printed in biocompatible materials like titanium or PEEK.5

Custom Prosthetics: Traditional prosthetics are notoriously expensive and can take a long time to manufacture. 3D printing has become a game-changer, particularly for amputees. It allows for the rapid and affordable production of lightweight, custom-fit prosthetic limbs. The ability to quickly create a new prosthetic is especially beneficial for children, who outgrow their devices frequently. The digital nature of the process also allows for a high degree of personalization in the design and color, improving the patient's experience.42

Surgical Planning and Guides: One of the most impactful applications is the creation of precise, 3D-printed anatomical models based on a patient's scans. These models allow surgeons to hold an exact replica of the patient's organ or bone in their hands before an operation. They can use these models to plan complex procedures, practice difficult surgical maneuvers, and anticipate potential challenges. This "dry run" enhances surgical precision, reduces time in the operating room, and ultimately lowers risks for the patient.3 Furthermore, custom surgical guides can be printed to fit perfectly onto a patient's bone, ensuring that cuts and drill holes are made with exact precision.

9.3 Case Study: Consumer Goods

In the consumer goods sector, 3D printing is enabling a shift away from the traditional "one-size-fits-all" model of mass production towards a new era of mass customization and on-demand manufacturing.

Mass Customization: Historically, producing customized products was prohibitively expensive due to the need for unique molds or tooling for each variation. 3D printing eliminates this barrier, as the cost to print one unique item is the same as the cost to print one thousand identical items.1 This has opened the door to mass-market personalized products. Examples include custom-fit earbuds created from a smartphone scan of a person's ear, personalized protective phone cases with unique designs and textures, and even fully 3D-printed footwear tailored to the wearer's foot shape and gait.1

On-Demand Manufacturing: 3D printing allows companies to adopt a "print-on-demand" model, producing goods only after an order has been placed. This radically streamlines the supply chain by minimizing the need for large inventories, reducing waste from unsold products, and allowing for an almost infinite variety of designs to be offered without any upfront tooling costs.1

Complex Geometries for Design Freedom: The technology liberates product designers from the constraints of traditional manufacturing methods like injection molding. They can now create products with intricate patterns, complex internal features, and novel aesthetics that were previously impossible to produce at scale. This unleashes creativity and allows for the development of innovative new products with enhanced functionality and visual appeal.1

Across these diverse industries, a common thread emerges. The fundamental value of 3D printing is its ability to produce complex, customized objects as easily and affordably as simple, standardized ones. This is not merely an incremental improvement on existing manufacturing; it represents a new economic model. It empowers businesses to move beyond the industrial-era paradigm of mass production and embrace a future of highly tailored, on-demand products and services. This has profound implications for every aspect of commerce, from more efficient and sustainable supply chains to more innovative product designs and, most importantly, to solutions and experiences that are perfectly matched to the unique needs of every individual customer or patient.

Conclusion: The Future of Manufacturing

10.1 Key Trends and Future Outlook

The analysis of the end-to-end 3D printing workflow reveals a technology that has matured far beyond its origins in rapid prototyping and is now a significant force in mainstream manufacturing. The trajectory of additive manufacturing is being shaped by several key trends that will define its future impact.

Material Science Innovation: The continued expansion of 3D printing into new applications is fundamentally a materials science challenge. The future will see the development and commercialization of an even broader array of materials with novel properties: polymers with enhanced thermal and mechanical performance, metals with superior strength-to-weight ratios, and advanced composites. The emergence of multi-functional materials—those that are conductive, self-healing, or possess embedded sensing capabilities—will unlock applications that are currently in the realm of science fiction.

AI and Automation: Artificial intelligence is becoming deeply integrated into the workflow. In the design phase, generative design algorithms will continue to evolve, producing ever more sophisticated and optimized solutions with less human input. A critical area for future development is the automation of post-processing. The transition from manual, labor-intensive finishing to fully automated systems for support removal, surface finishing, and quality control is essential for 3D printing to achieve the scalability required for true mass production.

Supply Chain Integration and Distributed Manufacturing: 3D printing is a key enabler of a shift from centralized, global supply chains to a model of distributed, on-demand manufacturing. As the technology becomes more reliable and accessible, it will become increasingly feasible to produce parts and products locally, close to the point of need. This reduces reliance on long-distance shipping, minimizes inventory, and creates more resilient and agile supply chains that can respond rapidly to changing demand.

10.2 Final Recommendations for Adoption and Implementation

For businesses, engineers, and designers looking to leverage the transformative potential of additive manufacturing, a strategic and holistic approach is paramount. Success is not achieved by simply purchasing a 3D printer but by developing a deep, integrated understanding of the entire workflow.

Embrace Design for Additive Manufacturing (DFAM): The greatest value of 3D printing is unlocked during the design stage. Adopters must move beyond simply using the technology to replicate parts designed for traditional manufacturing. Instead, they should actively embrace DFAM principles—leveraging part consolidation, topology optimization, and complex geometries—to create innovative products that are lighter, stronger, and more functional.

Think Holistically About the Workflow: The true cost and lead time of a 3D printed part are determined by the sum of all four stages: modeling, slicing, printing, and post-processing. A comprehensive analysis must account for the labor, time, and capital costs associated with each step. Overlooking the "hidden factory" of post-processing is a common pitfall that can lead to inaccurate cost assessments and failed projects.

Invest in Knowledge, Not Just Hardware: The most critical investment is in the education and training of personnel. A skilled operator who understands the nuances of slicer settings, material properties, and post-processing techniques can produce superior results from a mid-range machine than an unskilled operator with a high-end system. Mastery of the software and processes is the key to maximizing the return on investment in hardware.

Adopt a Technology-Agnostic Approach: No single 3D printing technology is superior in all applications. FDM, SLA, and SLS each have distinct strengths and weaknesses. A strategic adoption of additive manufacturing involves selecting the right tool for the job, matching the specific requirements of the application—be it cost, resolution, or mechanical strength—to the optimal technology and material combination.

By internalizing these principles, organizations and individuals can move beyond viewing 3D printing as a novelty and begin to harness its full potential as a powerful, flexible, and economically disruptive force that is fundamentally reshaping the future of how we design, make, and distribute physical objects.

Works cited

3D Printing in consumer electronics | Dassault Systèmes, accessed October 14, 2025, https://www.3ds.com/make/solutions/industries/3d-printing-consumer-electronics

3D Printing Technology in Aerospace Industry – A Review - Scholarly Commons, accessed October 14, 2025, https://commons.erau.edu/cgi/viewcontent.cgi?article=1708&context=ijaaa

3D Printing in Healthcare: Use Cases & Benefits - Appinventiv, accessed October 14, 2025, https://appinventiv.com/blog/3d-printing-in-healthcare/

SLA vs. FDM: Comparing Common 3D Printing Technologies - Protolabs, accessed October 14, 2025, https://www.protolabs.com/resources/blog/prototyping-technologies-for-3d-printing-sla-vs-fdm/

Medical Applications of 3D Printing and Standardization Issues - PMC, accessed October 14, 2025, https://pmc.ncbi.nlm.nih.gov/articles/PMC10409621/

Maximizing your 3D Printing Workflow - 3YourMind, accessed October 14, 2025, https://www.3yourmind.com/hubfs/3YOURMINDSolidEdgeMaximizing3DPrinting.pdf

3D Printing in Aerospace: Revolutionizing Part Manufacturing ..., accessed October 14, 2025, https://prototek.com/article/3d-printing-in-aerospace-revolutionizing-component-manufacturing/

How Additive Manufacturing Is Changing Aerospace Production, accessed October 14, 2025, https://www.aerodefevent.com/news/additive-manufacturing-aerospace/

3D Printing for Aerospace: Prototyping and Tooling - Xometry, accessed October 14, 2025, https://www.xometry.com/resources/3d-printing/3d-printing-aerospace-prototyping-and-tooling/

HOW 3D PRINTING IS CHANGING THE AEROSPACE INDUSTRY - Bowman 3D, accessed October 14, 2025, https://www.bowman3d.com/blog/how-3d-printing-is-changing-the-aerospace-industry

How to 3D Print: A Step-By-Step Guide of 3D Printing - Raise 3D, accessed October 14, 2025, https://www.raise3d.com/academy/how-to-3d-print-a-step-by-step-guide-of-3d-printing/

Workflow: Basics of 3D Design and 3D Printing : 7 Steps (with Pictures) - Instructables, accessed October 14, 2025, https://www.instructables.com/Into-to-3D-Design-and-3D-Printing/

Post-processing in 3D printing|Beamler, accessed October 14, 2025, https://www.beamler.com/post-processing-3d-printing/

FDM vs. SLA vs. SLS: Which 3D Printer Is Easiest to Use? - YouTube, accessed October 14, 2025, https://www.youtube.com/watch?v=4wHonWbx3fo

The Complete Guide to 3D Printing Post Processing - Wevolver, accessed October 14, 2025, https://www.wevolver.com/article/the-ultimate-guide-to-3d-printing-post-processing-techniques

FDM vs SLA vs SLS: The Ultimate 3D Printing Comparison - Jaycon ..., accessed October 14, 2025, https://www.jaycon.com/fdm-vs-sla-vs-sls-the-ultimate-3d-printing-comparison/

3D Printing Materials: Guide to Filament & Resin Types for 3D ..., accessed October 14, 2025, https://www.raise3d.com/blog/3d-printing-materials/

3D CAD Software for 3D Printing | SOLIDWORKS for Makers, accessed October 14, 2025, https://www.solidworks.com/solution/solidworks-makers/3d-cad-printing-software

3D Modeling Software for 3D Printing | Autodesk, accessed October 14, 2025, https://www.autodesk.com/solutions/3d-modeling-for-3d-printing

3D Design Software | 3D CAD Design - Autodesk, accessed October 14, 2025, https://www.autodesk.com/solutions/3d-design-software

3MF file format and why it's great - Original Prusa 3D Printers, accessed October 14, 2025, https://blog.prusa3d.com/3mf-file-format-and-why-its-great_30986/

3D Printing File Formats Compared: STL, AMF, 3MF and OBJ | Xometry Pro, accessed October 14, 2025, https://xometry.pro/en/articles/3d-printing-file-formats/

Understanding 3D Printer File Formats (STL, OBJ, 3MF, and more) - Wevolver, accessed October 14, 2025, https://www.wevolver.com/article/3d-printer-file-formats-stl-obj-3mf

Last Guide to 3D Print File Type You'll Ever Need – einstar, accessed October 14, 2025, https://www.einstar.com/blogs/einstar-academy/3d-print-file-type

Understanding G-code 3D Printing: Essential Commands and Slicer ..., accessed October 14, 2025, https://www.3dmag.com/3d-wikipedia/g-code-3d-printing-commands-slicer-output/

Slic3r - Open source 3D printing toolbox, accessed October 14, 2025, https://slic3r.org/

Beginners Guide to 3D Printing G-Code Commands | Simplify3D, accessed October 14, 2025, https://www.simplify3d.com/resources/articles/3d-printing-gcode-tutorial/

G-Code 3D Printing Commands: Tutorial, List & How to Use Them - JLC3DP, accessed October 14, 2025, https://jlc3dp.com/blog/g-code-3d-printing-commands-tutorial-list-how-to-use-them

SLA vs SLS vs FDM: comprehensive 3D printing comparison - Sinterit – Professional SLS 3D Printers & Accessories, accessed October 14, 2025, https://sinterit.com/blog/sls-technology/fdm-vs-sla-vs-sls-comparison/

Introduction to Medical 3D Printing and 3D Printers for Healthcare | Formlabs, accessed October 14, 2025, https://formlabs.com/blog/3d-printing-in-medicine-healthcare/

3D Printing Aerospace | Dassault Systèmes, accessed October 14, 2025, https://www.3ds.com/make/solutions/industries/3d-printing-aerospace

Guide to Materials Used in 3D Printing | SPC - Sharretts Plating, accessed October 14, 2025, https://www.sharrettsplating.com/blog/materials-used-3d-printing/

www.google.com, accessed October 14, 2025, https://www.google.com/search?q=materials+used+in+3D+printing

POST-PROCESSING YOUR 3D PRINTS, accessed October 14, 2025, https://www.unthsc.edu/center-for-innovative-learning/wp-content/uploads/sites/35/2018/10/Posteprocessing3dprints.pdf

Top 10 Thingiverse Alternatives of 2025 - Creality Cloud, accessed October 14, 2025, https://www.crealitycloud.com/blog/reviews/alternatives-to-thingiverse

Thingiverse - Digital Designs for Physical Objects, accessed October 14, 2025, https://www.thingiverse.com/

What is the Most Popular 3D Model Repository? - Fabbaloo, accessed October 14, 2025, https://www.fabbaloo.com/news/what-is-the-most-popular-3d-model-repository

2024 Best Thingiverse Alternatives For 3D Printing STL Files - anycubic-store, accessed October 14, 2025, https://store.anycubic.com/blogs/3d-printing-guides/best-thingiverse-alternatives-for-3d-printing

Cults・Download free 3D printer models・STL, OBJ, 3MF, CAD, accessed October 14, 2025, https://cults3d.com/en

Top 20 Websites to Download STL Files for 3D Printing, accessed October 14, 2025, https://www.dobot-robots.com/insights/news/top-20-websites-to-download-stl-files-for-3d-printing.html